100% automatic driving ranges: what concrete solutions are there in Europe?

Automating a golf driving range reduces reliance on labour, provides continuous service (collection, washing, dispensing), improves the quality of the grass, and reduces emissions and noise. The European solutions presented here combine Belrobotics robotic mowers (Bigmow + BallPicker) and ball management systems (Vos Capelle, VDB Technics, AMS Robotics, Range Servant).

Why automate a driving range in 2026?

Staff shortages and peak times

Automation ensures uninterrupted collection and return to the dispensers, even early in the morning, late in the evening, and over the weekend. Belrobotics professional robotic mowers operate continuously, with low average energy consumption (up to 830 kWh/year for the biggest models), which makes them very attractive.

Quality of play and service

The Bigmow mows silently without damaging any balls thanks to its patented guard discs, whilst the BallPicker collects balls autonomously and is able to concentrate on high-density areas. It then takes the balls back to the drop-off area, where they are washed and then redistributed. The result: a tidy driving range and a regular stock of balls.

Sustainability & image

By using these electrical solutions, you can reduce emissions (CO₂ approximately 10 times lower than mowers with combustion engines) and noise (max. 58 dB(A)). In addition, frequent mulching promotes a dense, healthy lawn.

How to choose the right configuration for your driving range

1. Ball volume

The traffic determines the size of the system. A large number of balls per day requires a high-capacity drop pit and washer. For smaller volumes, a simpler system on the ground is sufficient.

2. Available space

The choice between an underground or a compact system depends on the layout and the distances between the drop pit and the dispenser.

3. Level of automation

Some systems cover the whole cycle (collection, washing, conveying). Others operate in stages, with the possibility of adding modules later.

4. Tracking and management

Some systems include automatic ball counting, which is useful in keeping track of stock. Other systems rely on manual checks.

5. Constraints

Some systems are required to operate during the daytime, and sometimes near busy areas. It is therefore crucial to consider the size of a system and the need for it to be quiet.

Which solutions does Belrobotics recommend?

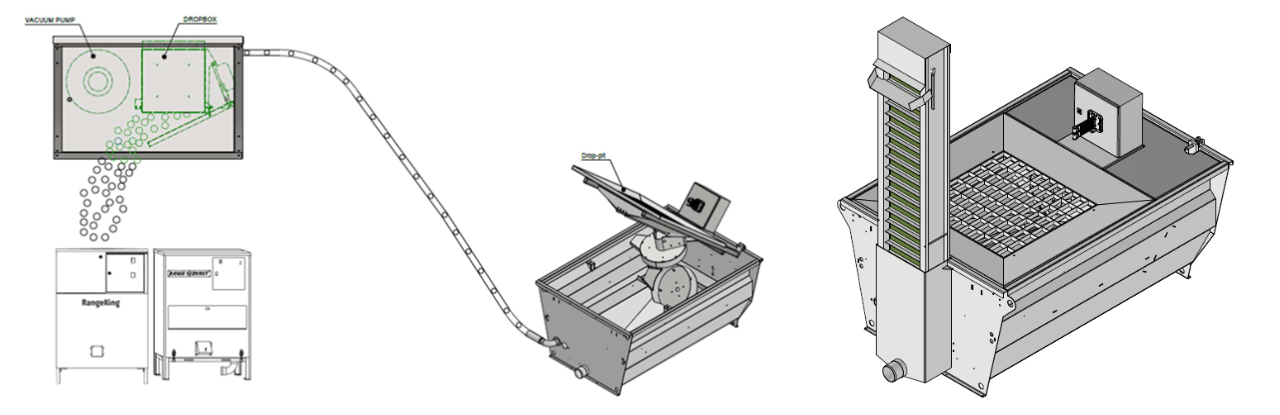

Range Servant – Golf Ball Ditch (Sweden)

Range Servant offers several ball reception solutions that are compatible with the BallPicker. Their system can integrate into a complete ball management system (pre-wash, wash, dispensing), which accelerates processing and can collect, store, and transfer driving range balls without manual handling.

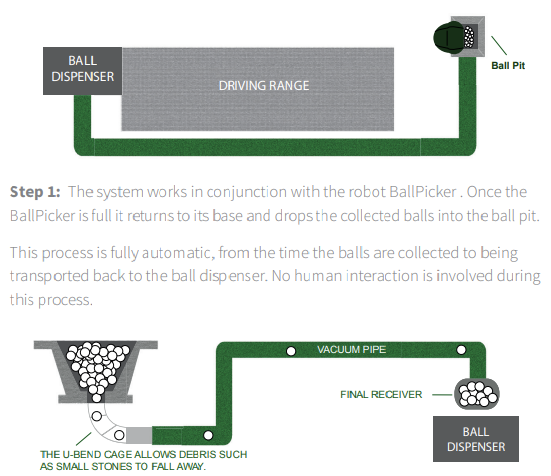

AMS Robotics – Automated Ball Management (United Kingdom)

AMS Robotics offers an integrated system based on transporting the washed balls to the dispenser via a negative pressure pipe. This approach simplifies the daily management of the driving range by automating the entire chain, from golf course to dispensing.

VDB Technics – Drop Pit Series (Belgium)

VDB Technics has designed the Drop Pit range, consisting of ground-based or underground solutions to wash, convey, and sometimes count balls after collection. These modular systems let you adjust the capacity and configuration according to the volume of play and the available space.

Vos Capelle – Vosca Range Solutions (Netherlands)

Vos Capelle has developed the Vosca Range Solutions system, a compact and robust solution for automatic ball collection and return on driving ranges. It aims to simplify the flow of balls between the collection area and the dispenser, whilst keeping manual interventions to a minimum.

Complementarity with Belrobotics robots

The advantage of these solutions is that they integrate naturally with Bigmow and BallPicker robots. Through them, automation can extend to the whole ball management cycle, for continuous maintenance and a driving range that is always operational without creating any complicated layouts to connect the whole system.

Frequently asked questions

Are these solutions 100% compatible with Bigmow & BallPicker?

Yes. Vos Capelle and AMS Robotics design their chains around the Belrobotics ecosystem, and VDB Technics and Range Servant size the drop zone for BallPicker’s automatic drop-off function.

Does continuous mowing, ball picking, and automation damage the balls?

No, not in well-designed systems. Mowing robots use guard discs to protect the balls. In our partners’ ball management modules, the drop-off, washing, and transport processes are designed to minimise impact and to handle the balls carefully.

What is the environmental impact of these systems?

The whole system is 100% electrical and it operates with low power consumption. This significantly reduces CO₂ emissions and noise.

How are the balls cleaned in automatic systems?

Different manufacturers apply different methods: some use water washing, where the balls are brushed and then transported by negative pressure to the dispenser. Others incorporate washing directly into the suction pipe, with continuous rinsing and drying. Finally, certain more compact solutions use hydraulic transport, where the water flow carries the balls and washes them at the same time. In any case, water consumption remains low and the process aims to protect the quality of the balls whilst reducing manual interventions.

Is an automated driving range noisy?

Automatic maintenance systems operate mostly on electricity, which makes them much quieter than internal combustion machines. This means that the mowing and picking robots can work early in the morning or at night without disturbing players or local residents. The washing and transport modules generally use closed hydraulic or negative pressure processes, where noise is only occasional and is contained within the technical area. Overall, these systems extend the operation of the driving range whilst maintaining a calm, discreet environment.