When to replace your robot mower blades?

The replacement frequency of the blades of a robot mower depends on the model, its use and your ground. Our experience in the matter allows us to state that the blades of professional robot mowers have to be replaced every 2 to 6 weeks to ensure a superior quality of cut.

It is impossible to compare the service life of robot mower blades for large surfaces with conventional models sold in the trade. Professional robots function during long periods, over very large areas (sometimes up to 20 000 m²). Accelerated wear of this element, crucial for a perfect cut is thus essential. Then again, the process can be slowed down if you remember to follow some advice.

Good practice: we strongly recommend that you check the condition of this part of your robot each week after installation and at the beginning of each season after its winter rest. After several weeks of use you will have formed a more precise idea of the useful service life of your robot mower blades depending on the conditions of your green space or sports ground.

Frequent breakdowns and their causes

In many situations a damaged or blunted blade is caused by an element of the ground. Here is a list of the most frequent breakdowns and their causes to allow you to increase the useful service life of your robot blades and avoid as many problems as possible.

1. The cutting edge of the blade is too worn, reducing the quality of the mulching, and provoking eventual damage to the lawn

Situations that might result in a problem

a. Cutting long grass in a single pass

To avoid premature blunting of the blade’s cutting edge, it is advised to adjust the cutting height to 5 mm or 10 mm under the length of the grass and to proceed in several cutting passes. It is important to allow for this situation, particularly during the first mows at the start of the season.

b. The blade comes into contact with a lump of earth

If a bump is too high or a hole too deep, the pantograph, which allows the blades to follow the lines of the ground, will not function correctly and the blade may hit against the ground, which will soon blunt it. It is therefore best to first make sure that there are no very high bumps or deep holes in your ground and either to level any such unevenness down or up, as the case may be, or exclude them from the mowing zone.

c. The blade comes into contact with a nylon ground marker

Nylon ground markers may not actually be obstacles that are hard enough to break a blade, but they can still blunt it through repeated impact. It is therefore recommended to lower them below your cutting height.

2. The end of the blade is bent or broken making the mower inoperable

Situations that might cause such a problem

a. The blade has hit a solid obstacle (sprinkler, stone, root, waste, …)

If it is a useful obstacle like a sprinkler you can try to lower it so that the robot mower can pass over it without touching. You can also adjust your cutting height higher than the obstacle or change the run of the peripheral cable to set the obstacle outside the mowing zone.

b. The blade has hit a removable goal

The metal parts at the base of these goals are sometimes undetectable. It is therefore advised to exclude them from the mowing zone in order to avoid any problem.

3. The blade has a gap of more than 2 mm or the blade has disappeared

In certain situations the screw hole may be worn and become wider, creating a gap or resulting in the loss of one of the blades. If you note a gap of more than 2 mm it is possible that an element of your ground might be the cause.

Situations that might cause such a problem

a. The blade has hit a molehill

The earth of a molehill slows down or even stops the blade. Once past the obstacle, the blade returns to a normal speed. The resistance of the obstacle implies that the blades will grind for a while. The active energy might then loosen the screws (or damage the screw hole). It is therefore advised to remove any molehills from your ground.

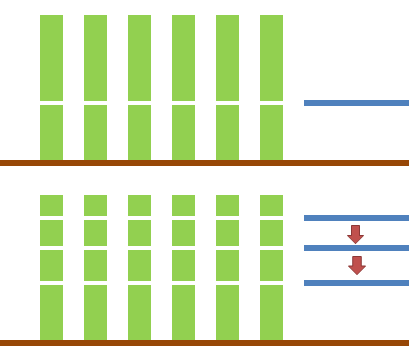

b. Your ground has bare patches

If the blade moves from a grassy zone to a bare zone its rotation speed will change, since there is no longer resistance. If this speed shift occurs too often it might damage the pivot and the screw hole. To avoid this problem you can adjust the cutting height to reduce the speed difference between zones with and without grass cover (the less the mower has to cut, the less its speed is therefore impacted).

c. Your ground has furrows

Furrows may appear, for instance, near the charging station. The blade may then hit the raised edges of the furrows which, besides blunting the blade, may induce excessive pressure on the pivot, as the blade bites into the ground. It is therefore advised to level the ground to avoid any problem or to lay an artificial turf that will avoid furrows.

Since update 4.2 of our software our robot mowers can cut different plots to different heights. It might therefore be a good idea to increase the cutting height in the zone near the station.

d. Zone next to your peripheral cable is grown with tall weeds

Weeds of a certain height, growing just at the limit of the cable, may still be hit by the blades of heads 1, 3 and 5. This can blunt or damage the blade, according to the type of weed. It is therefore preferable to keep clear the areas around your peripheral cables.

4. Other causes

a. The pantograph is loose

The pantograph allows the blade to follow the curves of the ground. In certain situations, however, the arm of the pantograph may have worked itself loose. The blade is then inclined. In such a situation that blade will cut or touch the ground deeper than the other blades. You can suspect and visually detect such a problem when a particular blade appears to be wearing faster than the rest. It will then be necessary to replace the affected parts of the pantograph.

b. The pantograph does not move smoothly

In certain situations the pantograph cannot move smoothly and, therefore, will be unable to follow the curves of the ground. The disc of the connected blade may then strike the ground and become blunted or break sooner than the rest. In such a situation it is important that you clean the pantograph. Consult your specialist if that does not remedy the problem.

Belrobotics works continuously to improve its blades so as to adapt them to a maximum number of possible scenarios and a maximum of possible grounds. However, in specific situations, the blades may age faster than anticipated. If that situation should occur on your ground after analysis of the various points mentioned in this article, do not hesitate to contact us so we can offer you our best assistance.